I least that's what I would have thought?

If it's a small error in ball diameter then it looks to me like it may not be noticable, and any large error would probably be seen by the user in FPX or the 2D view of the footprint in the CAD program first. I'm not sure how you can visually validate the footprint to ensure solder joint accuracy here since the user is probably going to be outputting the 3D model and the footprint from FPX at the same time so if they've an error input values then it's probably going to be a wrong pitch which would be same on both model and footprint, or the wrong ball diameter.

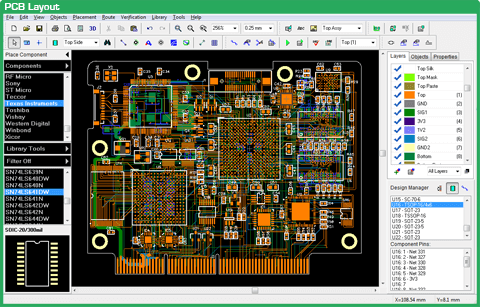

Pulsonix has a built in 3D viewer in addition to the STEP file preview and output and in Pulsonix I mainly use the built in 3D viewer for a quick check because the STEP file takes longer.

0 kommentar(er)

0 kommentar(er)